CMO

GC Wellbeing is with You,

from Pharmaceutical Development to Production.

Consignment Business

GC Wellbeing is a CDMO partner providing seamless technology transfer, clinical and commercial product manufacturing/production, aseptic filling (finished products), and analytical testing services.

From the moment GC Wellbeing meets you, our customers, we walk through the entire process with you, from product development to manufacturing. GC Wellbeing is committed to delivering value to our customers through our excellent products and quality assurance systems, both of which comply with current Good Manufacturing Practice (cGMP) regulations.

Customer Value is Our First Priority

Quality

We guarantee the highest quality and an unmatched production capacity with our exclusive GMP production facility.

Delivery

We promise prompt delivery with production facilities able to respond quickly to market fluctuations.

Price

Our mutually-beneficial pricing policy builds trust with our customers.

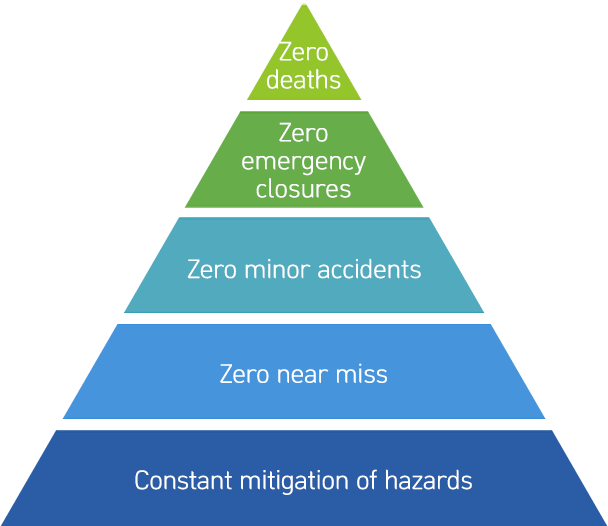

A Safe and Healthy Environment

GC Wellbeing Zero accidents for three years

Zero accidents for 14 years

Acquired ISO45001 for safety and health management system

We use a proven system to ensure

a more comfortable working environment.

GMP Approved

January 2023

CMO initiated

December 2022

Raw ingredients DMF approved

September 2022

Innovation Plant Operation

August 2022

GMP designation acquired for completed products

Items Available for Consignment

Production of general injections in ampule and vial formulations (e.g. preparation, filling, inspection, packaging, etc.)

Production of aseptic, sterilized, and refrigerated products.

Secondary packaging consignment & production.

Capacity

You can check it by moving it left and right.

| Category | Formulation | Capa. | Note |

|---|---|---|---|

| Charging line | Amp | 6.2 million Ampules | Overlap Tasks |

| Vial | 4.7 million Vials | ||

| Packaging line | Amp | 5.4 million Ampules | Overlap Tasks |

| Vial | 3.4 million Vials |

*Charging line: 2 ml Ampules/Vials

**Packaging line: Ampules: 250 RPM (2 ml)/ Vials: 150 RPM (25 ml) (stable & safe processing available, RPM)

Manufacturing Facilities

Charging line

| Category | Ampule charging and vial charging line |

|---|---|

| Producer | SYNTEGON (前 BOSCH) |

| Applicable standard | Amp: 1-10mL (Φ11.2-Φ17) |

| Vial: 2-25mL (Φ12-Φ30) | |

| Maximum speed | Max. 400rpm |

| Features | Barrier system (O-RABs) Application |

Packaging line

| Category | Ampule and vial packaging line |

|---|---|

| Line composition | Pinhole tester [Ampule only] , Automatic inspector for foreign substances |

| Labeler | |

| Cartoner | |

| Barcode printer & aggregation MC | |

| Applicable standard | Amp: 1mL-10mL x 10,50A |

| Vial: 2mL-25mL x 10V | |

| Maximum speed | Max. 400rpm |

| Features | In-line configuration of the entire packaging process Label print history / OCR vision detection |

CMO Contact

You can check it by moving it left and right.